Cases in China

Location: Shanghai, China

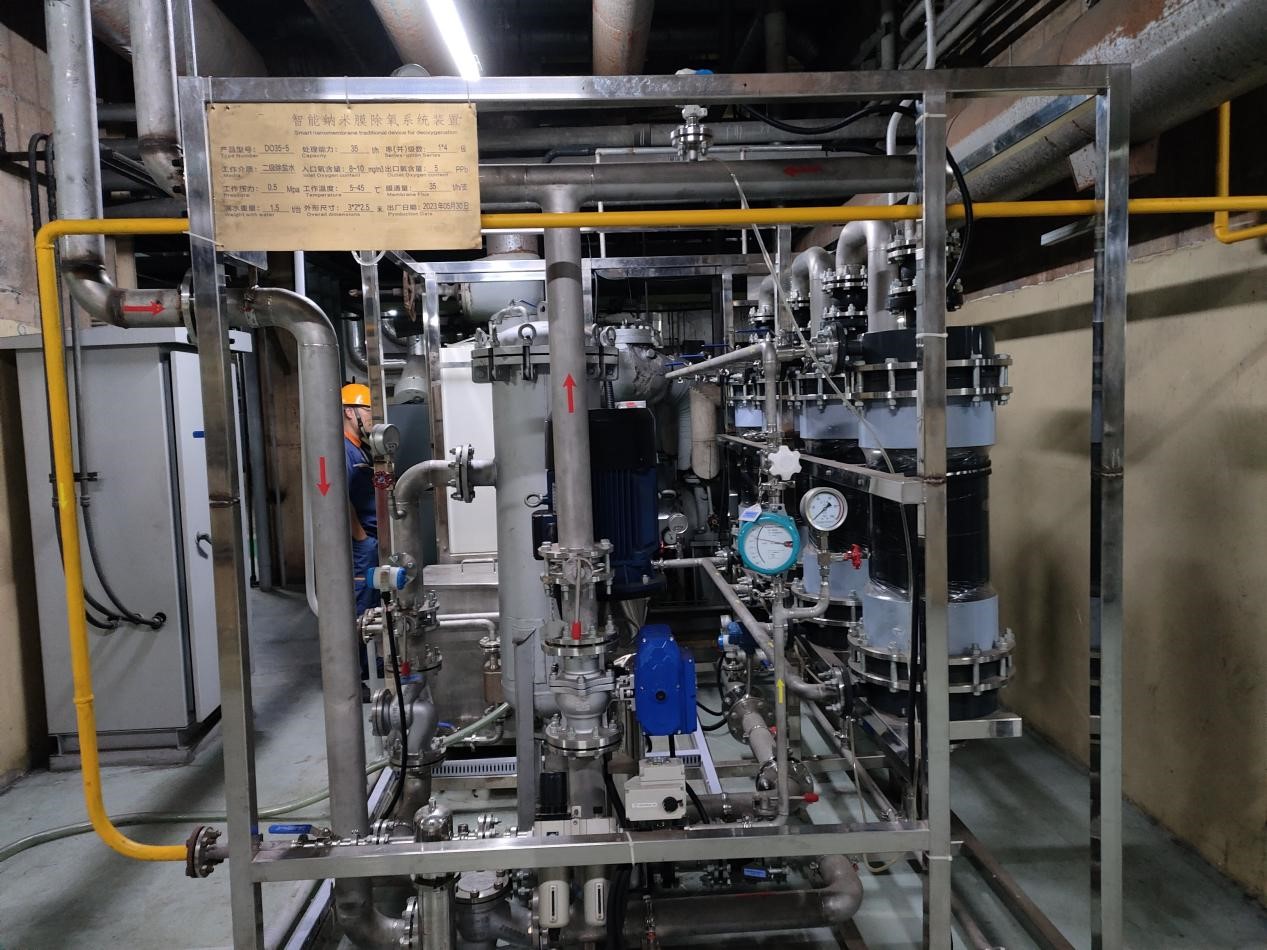

Plant: A 350MW pure condensing coal power plant

Industry Context: Traditional thermal deaerators consume significant steam and suffer from energy losses due to vent emissions.

Edgecross Solution: Utilizes a 35t/h membrane deaerator to remove dissolved oxygen (O₂) via vacuum & nitrogen sweep mode. Shut down the vent valve of the 1068t/h thermal deaerator to avoid vent loss. Lowers the heating steam amount used in thermal deaerator.

Technical Specifications: Achieves O₂ levels <1 ppb at the outlet of the membrane deaerator, <3ppb in condensing water in the condenser, and <5ppb in the thermal deaerator, all below the national standards for different kinds of water.

Innovation: A 35t/h membrane contact to replace a 1068t/h thermal deaerator.

Location: Shijiazhuang, Hebei Province, China

Plant: Two 473MW gas turbines with a 144MW recovery steam generator

Industry Context: Traditional thermal deaerators don't work well under frequent start-shut operation and high volume steam output to outer users. Corrosion occurs in boiler pipes.

Edgecross Solution: Utilizes a 60t/h membrane deaerator to remove dissolved oxygen (O₂) via vacuum & nitrogen sweep mode. Shut down the vent valve of the thermal deaerator to avoid vent loss.

Technical Specifications: In any variable operation, like frequent start-shut, changeable steam output, fluctuating feeding water temperature, etc., the membrane deaerator achieves O₂ levels <3 ppb steadily.

Innovation: A membrane deaerator that is suitable for variable working conditions.

Location: Beijing, China

Plant: SMIC (Semiconductor Manufacturing International Corporation)

Industry Challenge: Dissolved O₂ and CO₂ in ultrapure water can oxidize silicon wafers, compromising chip integrity.

Edgecross Technology: Membrane contactors are utilized in make up process for extreme degassing.

Performance Metrics: O₂ ≤1 ppb, CO₂≤1 ppm, critical for wafer cleaning and photolithography processes.

Reliability: Integrated 4S Service Model employs FMEA (Failure Mode and Effects Analysis) to preempt system failures, ensuring zero operational disruptions.

Location: Harbin, Heilongjiang province, China

Plant: Harbin Shuangcheng Wahaha Food and Beverage Co., Ltd.

Application: Decarbonation in beer, bottled water, and soft drinks to stabilize taste and extend shelf life.

Edgecross Solution: A 50t/h membrane decarbonization system strip CO₂ to replace traditional blowing tower to avoid contamination by air.

Performance: Reduces CO₂ to 1 ppm, outperforming traditional towers by 30% in efficiency.

Adaptability: Systems are modular, enabling easy scalability for production line expansions.

Location: Bohai Bay, China

Plant: China National Offshore Oil Corporation (CNOOC)

Challenge: Dissolved oxygen in reinjection water corrodes pipelines, shortening equipment lifespan.

Edgecross System: A 350t/h sea water deoxygenation system to replace traditional vacuum tower and to avoid chemical addition.

Case Results: Extremely low O₂ level achieved down to <5ppb processing sea water. Zero chemical addition. Reduced maintenance costs by 25% annually.

Robust Design: Operates reliably in harsh environments (e.g., high salinity, fluctuating temperatures).

Innovation: The world's most biggest membrane contactors were used to make the compact system, which makes the revamping project possible.

Location: Yulin, Guangxi Autonomous Region, China

Plant: China Rare Earth Group

Industry Focus: Treats wastewater from rare earth mining, coal chemical plants, and pharmaceutical facilities.

Technology: Hollow fiber membranes under acid absorbing conditions selectively remove ammonia nitrogen (NH₃-N).

Performance: Achieves NH₃-N levels <1 ppm, meeting stringent discharge regulations.

Operational Advantage:

Focuses on system reliability through FMEA-driven lifecycle management, ensuring zero on-site failures.

Reduces energy consumption by 30-50% versus thermal/chemical methods.

Tailored solutions for niche applications (e.g., high-purity semiconductor water, acidic wastewater).

"Edgecross's membrane deaerator cut our annual energy costs by ¥500,000 and simplified compliance with environmental standards."

"The system's modular design allowed seamless integration into our existing line, with no production downtime."

Edgecross leads the industry with proven expertise and innovative solutions, as demonstrated by our key achievements:

16+

16+ countries sales

20+

20+ industries served

>8000t/h

Degassing volume >8000t/h

>250Mw

energy-saving >250Mw

9yrs+

9yrs+ in purewater

4yrs+

4yrs+ in Deamination

0.1ppb

Less than 0.1ppb for O2

1ppm

Less than 1ppm for CO2

For technical parameters or industry-specific inquiries, please contact our engineering team directly.

Contact Us