Membrane Contactor - Engineered and Manufactured

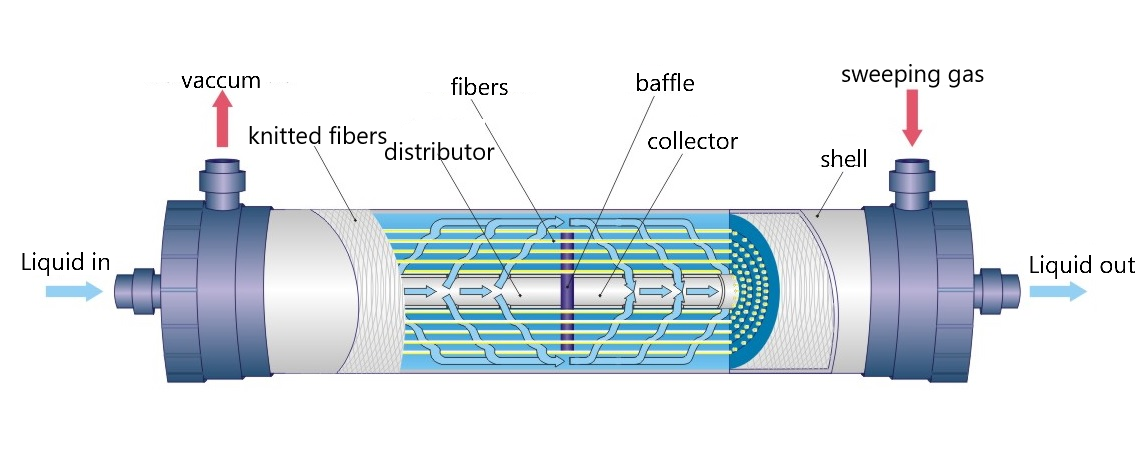

Our Membrane Contactor adopts a patented structure of "knit+central dispenser+baffle", which gives the membrane contactor module a specific surface area 27 times that of traditional towers and achieves over 10 times higher mass transfer efficiency.

Edgecross membrane is made from polypropylene (PP) by hollow fiber spinning-stretching process. The outstanding feature of Edgecross membrane is its high concentration of most probable pore size that is decisive to the material performance. By controlling the pore size, Edgecross membrane adjusts balance between gas penetration and water resistance pressure that is contradictory but required quite differently in various gas transfer and industrial applications.

Due to self-developed pore size measurement methods and strict quality control, Edgecross membrane has very high pore size distribution stability in mass production. Uniform material quality is the foundation for further performances of contactors and contacting systems.

Exploded View

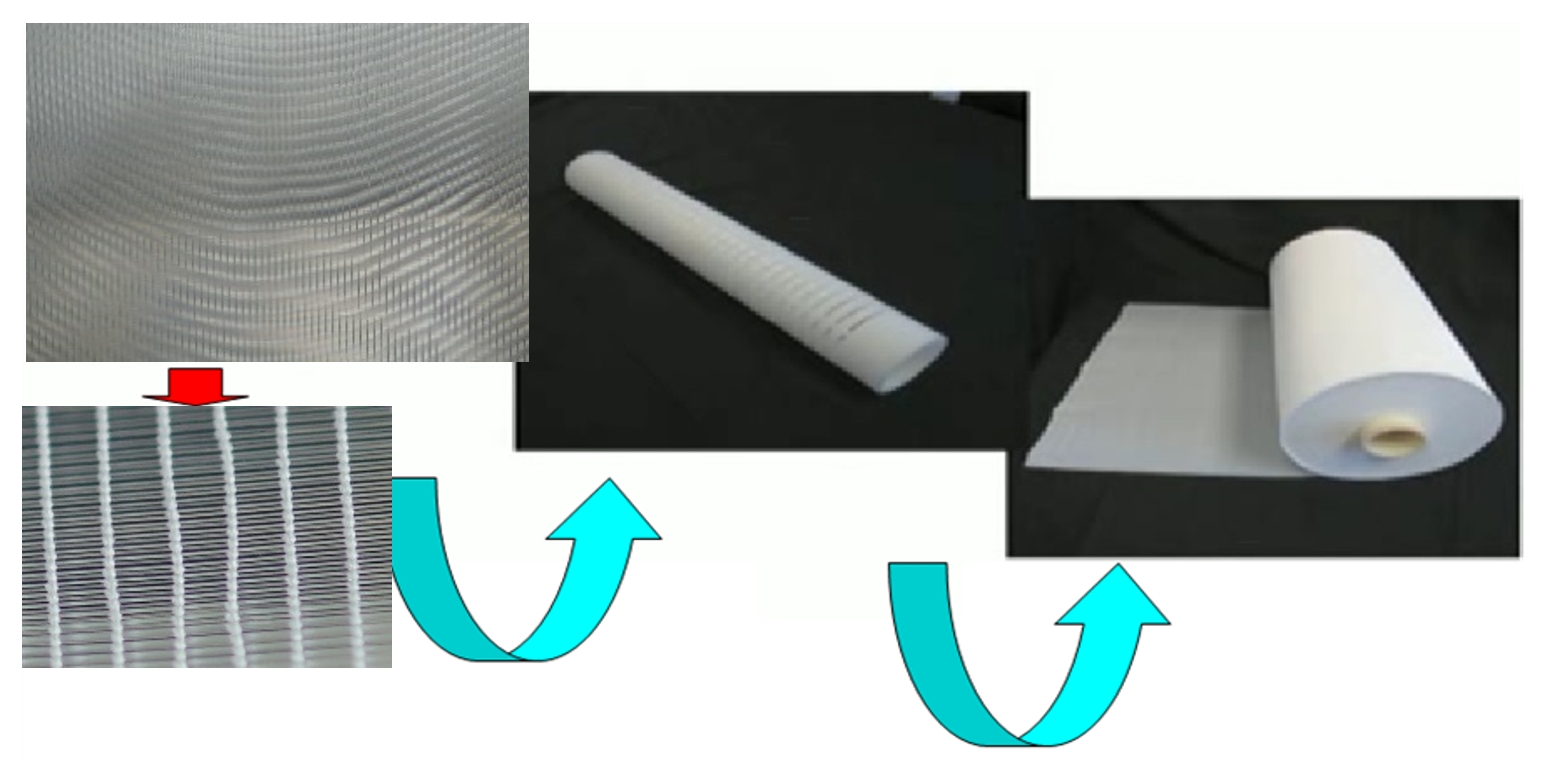

Core Components

Membrane Contactor Overview

Hollow Fiber Membrane Filament

Membrane Tube Wall (Microscopic View)

Cross-section of Hollow Fiber

Product Series

ETO Series

Purpose: Oxygen (O₂) Degassing

This series features high water resistance pressure and low gas penetration, designed for applications with minimal dissolved oxygen in water. For ultra-pure water applications, all materials (piping, potting epoxy, and gaskets) are super-clean and educt-free.

Ideal for semiconductor-grade ultrapure water with O₂ concentration requirements below 1ppb.

View ETO Proudct List →ETC Series

Purpose: Carbon Dioxide (CO₂) Degassing

Compared to the ETO series, these products have identical sizes and connection nozzles but slightly lower water resistance pressure and higher gas penetration due to higher CO₂ solubility in water.

Perfect for applications requiring removal of dissolved carbon dioxide from process water.

ETJ Series

Purpose: Ammonia (NH₃) Degassing

This series has the lowest water resistance pressure but highest gas penetration to remove large amounts of dissolved ammonia from water. The fiber surface is coated with hydrophobic chemicals for improved contamination resistance.

Features extended service life in wastewater applications and industrial ammonia removal processes.

Complete Systems & Solutions

Membrane Deaerator Systems

A membrane deaerator is a device that controls the dissolved oxygen content in water through membrane contactors. It is commonly used for removing dissolved oxygen from boiler feedwater or other deionized water.

Modern membrane deaerators feature highly efficient structural designs, enabling their mass transfer efficiency to exceed that of traditional contact towers (vacuum towers, absorption towers, desorption towers, etc.) by more than ten times.

In applications where dissolved oxygen in water is highly critical, such as ultra-pure water for semiconductors (O₂ dissolution <1 ppb) and feedwater for high-pressure boilers (O₂ dissolution <7 ppb), it offers significant advantages.

View 100t/h Deaerator Part List →

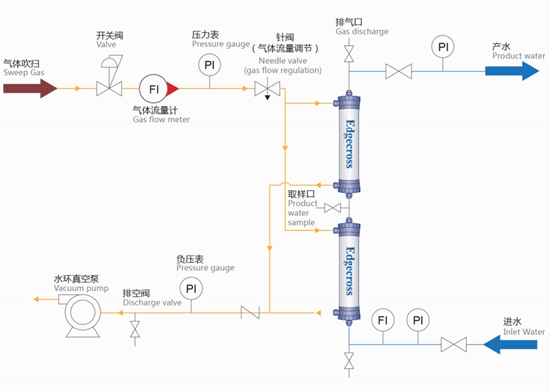

Combined Deoxygenation Process

To ensure that the produced water reaches a relatively low dissolved oxygen level (<300 ppb), a combined deoxygenation mode of "vacuum + sweep" is typically employed.

The membrane module consists of a water side and an air side. The water side processes pure water that needs deoxygenation, while the air side introduces a small amount of high-purity nitrogen gas at one end and extracts vacuum at the other.

The feed water passes through 2 to 4 stages of membrane contactor modules, reducing the dissolved oxygen to the desired level. The water pressure decreases by 0.1~0.3MPa. All removed gases are extracted under vacuum from the bottom of the air side by a vacuum pump.

Manufacturing and On-Site Running Equipment

All our equipment is produced in a state-of-the-art, highly automated workshop, ensuring precision, consistency, and exceptional quality control.

Installed in a deaerator system

Installed in a decarbonization system

Application Areas

🔹 Deoxygenation of Pure Water

- • Membrane modules for semiconductor-grade ultrapure water

- • Boiler system upgrades for energy saving and efficiency

- • Petrochemical & coal chemical: "oxygen-free demineralized water" for waste heat recovery and carbon reduction

- • HVAC & heating: corrosion prevention to extend pipeline lifespan and reduce maintenance

🔹 Ammonia Removal from Wastewater

- • Leachate from rare earth and non-ferrous metal mining

- • Wastewater from manganese and vanadium smelting & tailings

- • Cooling water from various gas sources

- • Landfill leachate treatment

Application Industries

Explore how our solutions are implemented across diverse industrial sectors. From power plant to wastewater treatment, discover industry-specific applications and success stories.

View All Application Industries →